_____Stu's___Dungeon__

Joyful Honda

Treasure

Lesson Room Cabs

In the beginning

2

3 4 5

6 7 8

9

10 11

12 13 14

15

Jointer1

Jointer2

Router

Table1

Router Table 2

The Doors

Do

Pa

Give Me A Brake

Cyclone

Cyclone 2

Cyclone

3

Cyclone 4

Liquor

Shop Reno Tenjinsama Shrine Tree Tour

Beer Shelves

Wine Shelves

Five Cuts

Drill Press <NEW

DoPa 2007 <NEW

Turning

Jean Francious Escoulen

Eli Avisera Demo Day One

Eli Avisera Day Two

Lathe Stand!!

Turning

Roughing

It

Sharpening Station

Bowl Blank Processing

Captured Hollowing Rig

<NEW

Logging In Tokyo

Woodlot Woodlot

2006 Woodlot

3 Woodlot 4

Chainsaw Mill

Chainsaw

Mill Mk II

Lathe Stand MkII

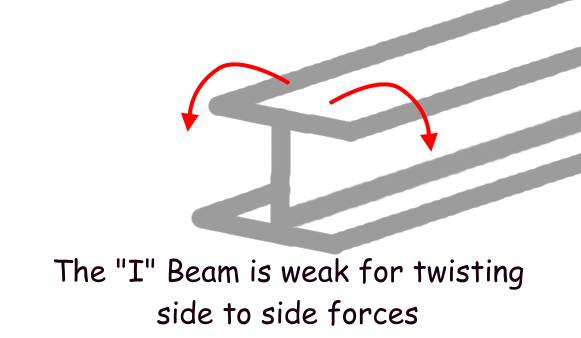

I made a stand for my lathe out of some I-beam, I thought it

would be good and strong, it was,

but it was also remarkably flexible!

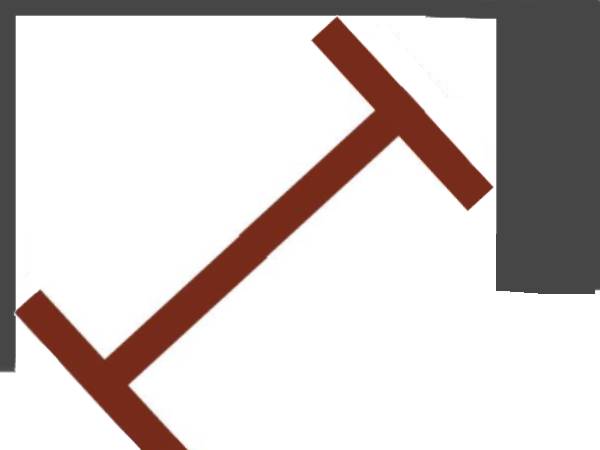

This is the stand I built in the beginning.

I did add some braces to the stand, and a box full of 80 kg of sand,

but, due to inherent side to side twisting of the I-beam, the stand was not good

and solid.

I also bolted the stand to the concrete floor, which transmitted

any sounds and vibrations to the whole building,

which was not good if I was trying to rough out a bowl at 2 AM......

I needed a new stand

I first temporarily tacked a longer brace to the stand

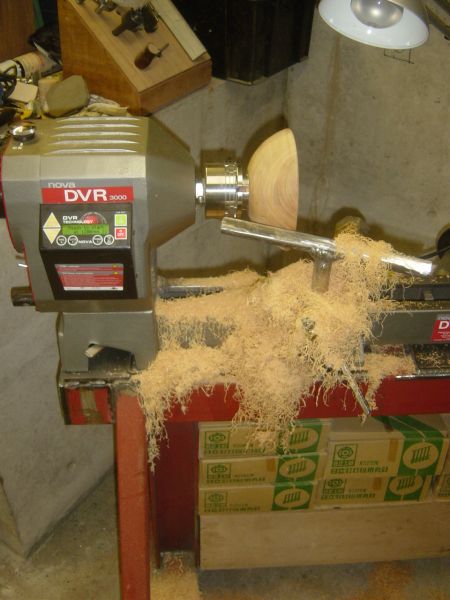

Here you can see the stand with the New DVR 3000 lathe mounted.

I tacked a piece of angle iron in place to see how it would stiffen up the

stand.

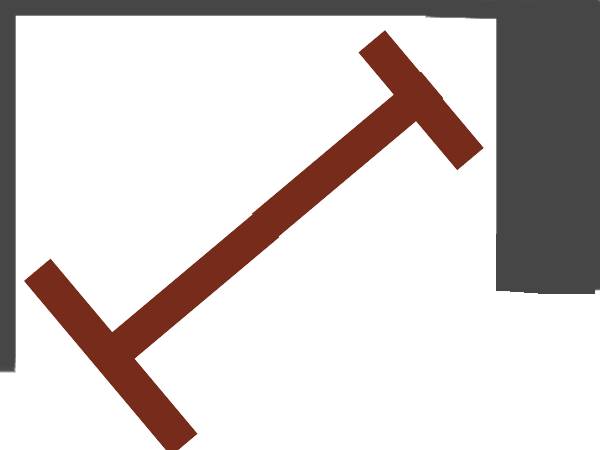

And another view. I found that the whole stand was much stiffer, which was good,

but I did not want to just do a "fix" I wanted it done for good.

I also want to make the stand wider, and stand alone, not bolted down to the

floor.

This is my idea to make it a lot wider.

.

Excuse the crude drawing, but this is the kind of thing I have in mind.

I'm going to box in the I-beam with some of this rectangular tubing,

I used this same stuff to make a stand for the jointer......

This stuff makes good stands

Good and solid.

I got this sucker up on the bench, boy it is heavy, but I'm going to add to

it....

OK, I've gotten down to the basic stand, I removed the braces,

and now I'm going to box in the I-beam on on top, as well as make some feet that

are wider

Here is a mock-up of what I want to do

With a bit of Photoshop added. I moved the sandbox support down lower, and I

made everything wider etc,

but the thing is I'm stuck for space, if I make the stand this size, I'll be

hitting the walls etc.

The space I'm using, I'll have to put the lathe on an angle to get it in there

and use the space best.

This pic has the tailstock and headstock ends with the feet the same length.

Here is a diagram with the tailstock end shorter. This should work.

This is a Vicmarc VL300, and it has a stand that is narrower on the tailstock

end.

OK, this is the headstock end, of the stand, I'm just test fitting here,

preparing for welding.

I've tacked the pieces in place, time to burn some wire!

Yep, spent time standing in front of the artificial sun for a while, but it is

just about there, on this end!

On to the tailstock end

Just test fitting here, but I think you can see how it will be.

The stand is in place, and the lathe is on for a test fit.

I'll drill and tap holes into the mounting plates, to bolt it down.

OK all bolted down, I also put the tool rest holder and the tailstock in place.

I chucked up a bowl, that came out of the DNA bath, it is out of round and

wobbled badly, the stand was rock solid!

I set this up so I can add one bed extension, when I get one.

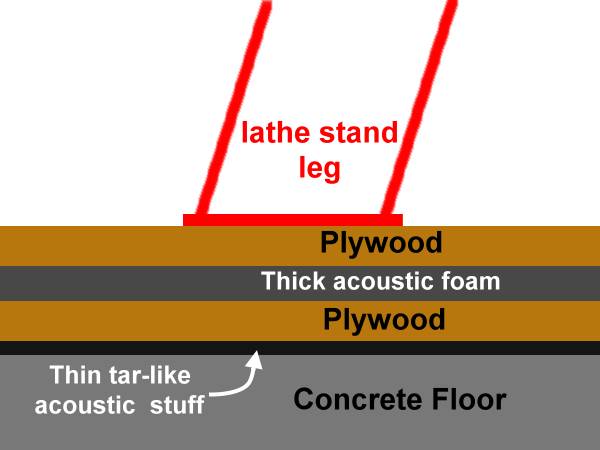

To further isolate the stand from the floor, I made up these isolation pads,

they seem to work.

Now I want to build an outboard tool rest, so when I turn the

headstock 90 degrees,

I'll be able to have a 21" swing over the stand, boy, that is some big

bowl!!

Maybe I'll even paint it...........?

OK, I got the last bits done...........

There is 100 Kg of sand in the sand box, a 25 Kg bag of cement and maybe another

50 kg or so of nails

I also made up a new tool rest, I like it very much!

Well that stand is ROCK solid, and runs smooth as silk, I was

finish turning a bowl on it,

and it was some HARD Red Keyaki, it was noisy, but even at 2 AM my lovely wife

did not call me on the interphone

to find out what I was doing, thus, mission accomplished!!

Cheers!