_____Stu's___Dungeon__

Joyful Honda

Treasure

Lesson Room Cabs

In the beginning

2

3 4 5

6 7 8

9

10 11

12 13 14

15

Jointer1

Jointer2

Router

Table1

Router Table 2

The Doors

Do

Pa

Give Me A Brake

Cyclone

Cyclone 2

Cyclone

3

Cyclone 4

Liquor

Shop Reno Tenjinsama Shrine Tree Tour

Beer Shelves

Wine Shelves

Five Cuts

Drill Press <NEW

DoPa 2007 <NEW

Turning

Jean Francious Escoulen

Eli Avisera Demo Day One

Eli Avisera Day Two

Lathe Stand!!

Turning

Roughing

It

Sharpening Station

Bowl Blank Processing

Captured Hollowing Rig

<NEW

Logging In Tokyo

Woodlot Woodlot

2006 Woodlot

3 Woodlot 4

Chainsaw Mill

Chainsaw

Mill Mk II

The Wood Lot Page Four!!

Feb 14th Happy Valentines Day!!

I

got to the wood lot fairly early, I lugged some of the boards up to the roof,

but man that is hard work,

and I was losing time, so I gave up, and went to the wood lot.

Yes another pic of the little van with a bunch of wood beside it.

This wood was from a crotch, and has AMAZING grain in it.

The reddish part is not a problem it is just as hard as the rest of the wood!

And a few more board on this side too. These were about 50 cm wide, and only 140

cm long by 4 cm thick.

(20" x 55" x 1 1/2")

The Tokyo Log Hog with the

newly ground ripping chain gnawed through this wood steadily,

I cannot say fast, as it was not, but steady. This wood is HARD, and at 50 cm

wide, that is a lot to cut!

Two cuts, and it was time to touch up the chain. If I did three cuts, well, the

saw would start making dust, so it was not worth it.

Some of

the logs were a little too wide to fit through the Tokyo Log Hog, so I trimmed

them,

These trimmed pieces were saved as bowl blanks.....

That is a 10" wrench in the pic. Nice burl eh?

The truck in port, ready to be unloaded (again).

Now around the wood lot I found out that they are going to save part of the house and the back old Japanese style room.....

I guess it will need major renovations, but the old wooden house is full of very

nice carved wood.

More stuff they are keeping, these stones and such

Everything with a blue ribbon they are keeping.

The last huge Keiyaki is down, they cut it down today.

Kind of neat how they did it, first they dug a hole on one side, then they cut

all the roots on that side,

and finally they pushed it over with the big excavator shovel. They did it

this way to make a soft landing and not crack the wood,

and they easily removed the root ball from the ground.

These guys use this fairly big Shindaiwa chainsaw, not bad.

They were enthralled to see me sharpening the chain on my saw, they asked me

what I was doing,

when I told them they looked a little stunned..... "Sharpen

it...?"

"Sure, why not, only takes a few minutes, and the saw works much better after that.

Well you see, when they get a

dull chain, the toss it, and put a new one on the saw (you can see the old chain

closer to me.

What a waste!

Now on the the "New" wood I'll be

getting in the next day or two.

The big Keiyaki is down, they only want the part from the stump to below the

first crotch, the rest is mine!!

Very nice color all the way through this log!!

More BIG stuff

And more and more!!

Tomorrow I'll get to this one...

This was the large crotch that looked like elephant legs,

I've trimmed it so the Tokyo Log Hog mill will slice it up.

One more thing, I broke my Cant today.....

I went flying, but I did not hurt myself, the metal actually tore, the weld

held!

That saw dust is getting deep!

Yep sure glad I'm doing this here and not in the Dungeon!!

February 15th

OK, I know that this page is getting rather long, but I've only got another day or so to go.

I had a great day, it was sunny and warm, really nice, so I got right at it and sliced up the crotch I had set-up yesterday....

I got 14 slabs out of it, there are some really nice ones in the middle, tons of

wavy grain!

Then I went on the the really red colored log I got yesterday, I has two crotches in it, one on each end....

I was pushing the capabilities of the Tokyo Log Hog to the max 52cm (20")

The wood that came off of this log is spectacular, some punky wood on one end,

but the rest of it is really nice......

I wish I could have gotten a better shot, but this is unreal stuff, there are

reds, brown, and whites in there, all fighting and twisting and turning....

You can see the punky stuff that needs to be removed in the two pieces on the

right, but the rest of the wood is really nice.

This is a huge crotch...........

There is some dead wood in it, so I do not know what this will yield,

I'm going to use the Big Husky free hand to slice it in two and take a

look,

at the very least, there are some cool bowl and pen blanks in there!!

This is what I have left for Thursday...

My poor little van..........

Da Big Log....

I've been talking about this LARGE Keiyaki log that the Demo company is keeping, well here it is.....

That hole only goes a couple of feet.

Here is a shot of the Japanese Crew, all nice guys, and very helpful.

As you can see that is no small log!!

Big boy on a big log....

February 16th

The Tokyo Log Hog has left the woodlot....

Yep, all done. I did leave a few pieces on the ground, but really, they were small potatoes, and I had to git-er-done

It rained hard last night, and the wood lot was muddy and it was cold today (for

Tokyo).

The day before it hit 20C, and today it was 6C in the morning, nice change!

I got a bunch of pieces, from a couple of different logs, the flaming crotch is

amazing!

I also cut up some interesting logs into bowl blanks, I sure home my lathe gets

here soon!

This is the left over from the from the bottom of the large log.

One of the guys at the wood lot asked me if I could slab it up

for him,

He wanted one piece about 2" thick, and another piece closer to 6"

thick.

I put the guide board on to take one thin slice off so it would start out fairly

flat.

I could not cut the slab in one slice, the slab was bigger than the Tokyo Log Hog.

I cut as much as I could, then I finished the cut with the big electric chainsaw.

One happy guy!

He will give one to his local shrine in his hometown, and the other to his son who recently got married and is building a house.

What they use these for is kind of a room divider,

they put them on edge, like in the picture,

then they write on them, usually with the brush to do the calligraphy.

They write the home owners name, or a famous saying, or personal motto etc.

This fellow was very helpful to me, and would always have time to come over with

one of the excavators to move a large log etc.

He always had something to say, teach or ask as well. I was glad I could help

him and make him one happy guy!

(BTW, he is making an "OK" sign, you can see this from

across a worksite, I don't know if this is used outside of Japan.)

Well that is it, I'm done. The sawdust is 8" deep in spots, I lost one

wedge and had to look for it for 5 minutes before I found it!

Basically the same spot when I started this adventure in early December, just

about two months ago.

There is the last load, now I have to take care of it all, stack it, sticker it,

and paint the ends.

It has been quite the ride!!

Notes

I just wanted to add a few things here about my process of cutting up these logs.

One of the things that I've heard a lot about is chains. I started with a regular cross cut chain,

this worked just OK, it was a lot of work to cut the hard wood, and left a very rough surface.

Next I re-filed my chain to what is called a ripping chain by some,

this is where the cutters are filed to a 5 degree angle on the cutters, but no cutter are removed.

This was an improvement over the standard cross cut chain, and I think it would work well on softer wood.

I next got directed to the Granberg style of ripping chain (thanks CJ & others),

the Granberg style Ripping chain has a set of teeth that have had every other set (pair) of top plates removed.

(A set meaning a tooth from each side when possible. See the picture below.)

You would take 2 teeth next to each other, one on one side and one on the other,

and grind off the top plates using a bench grinder, Dremel, or belt sander.

You don't shorten the tooth at all but merely remove the top plate that sticks out to the side of the side plate.

What's left on top is nothing wider than the thickness of the side plate.

The tooth with the top plate removed now goes through the wood with less resistance than pulling

a top plate along with it and effectively severs the wood fibers.

The next set of teeth to go through with the top plates, clean out all the severed fibers.

This results in less heat buildup, faster chain speed, and smoother cuts with reduced clogging.

This set up was a great improvement, the saw worked so much better using this chain.

I could keep the saw hogging through logs all day long, the saw would run just below the

"four stroking" you get when a saw hits it's rev limit, which is the peak of the saw's power band,

right where you want your saw to be running.

I ran the saw on good quality synthetic 2-smoke oil, at 32:1,

and I checked the plug frequently, and I always came back with a nice tan color on the plug.

The saw would smoke a bit on the first run in the morning, but from there, it was not smoky at all,

and there was only a slight build up of splooge on the muffler.

The saw, being an old one (circa 1976) Husky 85 cc was a bit of a handful to start in the morning,

having no decompression valve, but it would only take about 5 pulls to get it going in the morning.

Once it was run, it would always start on the 1st or second pull of the cord.

This was great, when I forgot to fill the saw, and I had to restart the the saw while in the log on a cut.

Some other things about the saw. Like I said, it is an old one, but this saw is good for milling (IMHO)

as it has the old style long stroke motor. It has a bit slower chain speed than more modern saws,

but I think this too is an advantage for milling.

The other thing that is good with this saw is that you can refill the gas and oil while the saw is on the mill,

sideways, but one bad thing is that I have to remove the mill to adjust the chain tension.

As the saw is heavy, it is not a bad choice for milling, the weight is on the log,

you are not carrying it around all day. If I had to lug this into the bush to cut lumber,

I'd be thinking twice about it, as well as my all steel milling attachment,

maybe I'd redo the whole thing in aluminum, but as I doing this off the back of my little van,

this set up is fine.

The fact that I bought it used for 28,000 yen ($250 US) also made it a great choice for me.

I started out filing only once or twice a day, I have to admit, filing chain is not exactly my idea of a good time!

Depending on the width of the log I was cutting, I'd sharpen the chain fairly often.

On the super wide boards, 50 cm (20") I found that with the Keyaki,

it was good to sharpen the chain every two or three boards. A lot of this wood was highly figured,

and I cut through a lot of crotches etc, so it was HARD work.

I found that by taking the time to sharpen the chain more often, I got nicer cuts and the saw worked better,

I guess my point is that if you are going to do this, take the time to sharpen you chain.

Something else that really helped was putting an auxiliary oiler on the milling unit,

it takes a bit of tweaking to get it right, but the extra oil on the bar makes a big difference.

If I where to be doing this on an ongoing basis, I'd change a few things,

one is I'd make some stands for

holding the logs off the ground...

(Something like this, they would have to be well built and wide, and stable.)

....

and I'd make a tripod with a chain hoist to lift the logs around, and onto the stands......

(I found these pics and a lot of great ideas on Bill's Wood Creations)

Putting the logs on stands would remove a lot of the grunt work, and keep you off the ground.

I was luck on all but the last day of my milling to be blessed with glorious sunshine,

but if you were doing this in the rain, or the snow, well,

standing up compared to kneeling, is obviously a great thing!

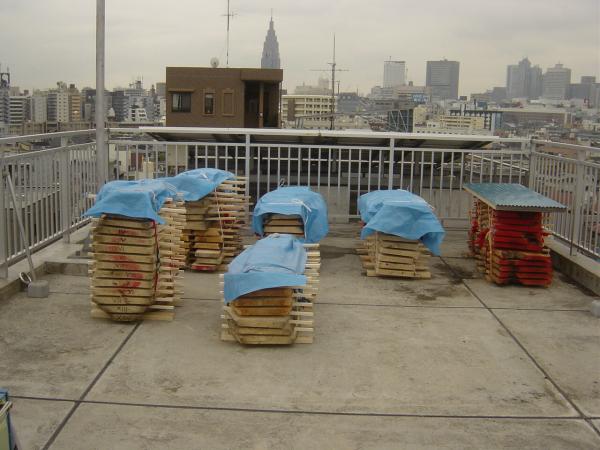

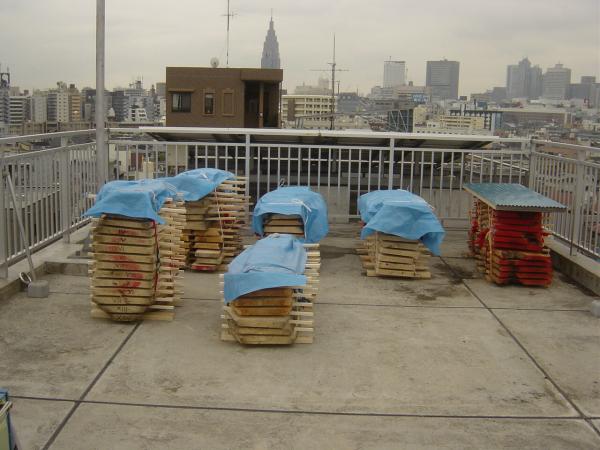

Up on the Rooftop

OK, I had my two buddies, Neil and Allen, come over and help me lug the boards up to the rooftop (thanks guys!!)

OK, I got it all stacked, and stickered.

Another view

Yet another view

Close up of the big stack of Red Keyaki

Another view

Yep, I sure like to take pictures

OK, last one....

Blue Keyaki & Red Keyaki, can you tell which is which....?

Rooftop view of the former woodlot, a dirt lot now.

That lot is 1000 Tsubo, or 82% of one acre...

You can see the local park, it is smaller than the wood lot was.

The view from the roof top, that is Shinjuku, Down Town Tokyo.

Some people think this is a beautiful view, I don't....

The view from my roof of our Liquor Shop

A closer view of the Liquor shop

The building next door, close eh?

OK, how about that for "Close"....

Down in the Dungeon Annex

OK, I got everything cut up and sealed that I wanted to, and I got it all moved into the Dungeon Annex.

As I cannot get AnchorSeal over here in Japan, I used hot wax, not the best thing, but it worked.

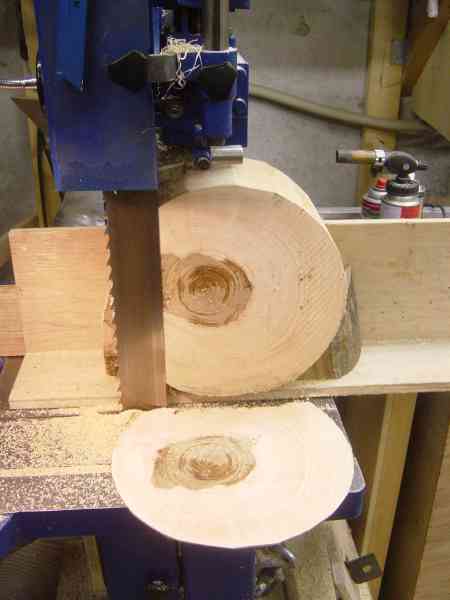

Some of the logs I had I cut up into blanks in the Dungeon.

Cutting around the pith in the center

The two chunks of wood on in front are going to be cutting blocks, the smaller

piece, will be on the lathe at some point.

On the last day of of cutting, I took a bunch of stuff that I'm going to make

into bowl and pen blanks.

Here is one I rough cut out on the bandsaw

A closer view

A second one

A small Keyaki bowl blank

Lots more to go

I sure hope my lathe gets here soon!!

Yep, lots on the table for me!!

One very large piece from the stump...

Cut up some pen blanks too

In total I ended up with 27 bowl blanks, 2 cutting blocks and well over 200 pen

blanks

I made this block of Keyaki a lot rounder on the bandsaw, and now I'm

using my sled to cut it square

Just taking off thin slices to square it up

Just about to start the second cut....

Second cut done....

I just took off enough to square it up, now I need to seal this so it does not

crack

First I put two stainless steel bands around it, to help it NOT crack

Then I poured hot melted candle wax on it

both sides, looks like a cake, or a big round of cheese!!

Here are my left overs, I'm going to leave them like this (paint the endgrain)

and figure it out later.

I then wanted my workshop back, so I moved all this stuff to the Dungeon Annex....

Here on top of the concrete block, is the turning blanks, all stacked and

stickered

The flat and round stuff co-existing

Some of the Akagashi stacked in behind the big stack of flat stuff.

The taller stuff with the "Y" at the top is Sakura.....

Some of the Sakura has cracked badly, I understand that this is why it is not

harvested here, it is very difficult to season it without this happening.

Big box of pen blanks. The shorter stuff on top is for practice and or bottle

stoppers etc.

I gave up counting after 200 blanks......

The chainsaws are put away for now......

While I was re-sawing some of this wood, I noticed that the blade was lacking

tension in Big Blue,

and I then checked the spring, sure enough, it is completely compressed!!! I

guess I need a new spring!!

I guess this ends my adventure in Logging in Tokyo, all in all I got some

Stacked, and covered

Cheers!

OK, an update

September 2006

I figure I have at least another year to go, but I can wait.

That is what the wood lot looks like now, they are gearing up to build two

apartment buildings.

There are the stacks, they seem to be just fine.

We had a bit of a rainy summer, so they are not as dry as I had hoped for, but I

can wait.