|

_____Stu's___Dungeon__

Joyful Honda

Treasure

Lesson Room Cabs

In the beginning

2

3 4 5

6 7 8

9

10 11

12 13 14

15

Jointer1

Jointer2

Router

Table1

Router Table 2

The Doors

Do

Pa

Give Me A Brake

Cyclone

Cyclone 2

Cyclone

3

Cyclone 4

Liquor

Shop Reno Tenjinsama Shrine Tree Tour

Beer Shelves

Wine Shelves

Five Cuts

Tod Evan's Doors

Building The Phoenix

The Phoenix Part II

Drill Press

<NEW

DoPa 2007

<NEW

Turning

Jean Francious Escoulen

Eli Avisera Demo Day One

Eli Avisera Day Two

Lathe Stand!!

Turning

Roughing

It

Sharpening Station

Bowl Blank Processing

Captured Hollowing Rig

<NEW

Logging In Tokyo

Woodlot Woodlot

2006 Woodlot

3 Woodlot 4

Chainsaw Mill

Chainsaw

Mill Mk II

Links

Other Stuff

| |

WORKSHOP PAGE TWO

More stuff done in the

Workshop!

Back to page one?

View of the cut-off sled I just made, works so well, I wonder how I ever

got along with out one! |

This is the 1st attempt, so it is a bit rough. I will use this one to make

cuts with the blade tiled, and I'll make another one for straight cuts,

and probably another for angled cuts! |

A view from the bottom of the stairs into the shop |

You can see my homemade dust collector here, it works, but it don't work

great. |

Rear view of the cut-off sled |

Front view |

I need to make a lumber rack of some sort |

I've got my CMS and my mini DP in a line on one bench I've built. seems to

work fine |

| Update

October 1st! |

Brand spanking new! |

even have a good push on/off switch that I can use somewhere. |

Rather basic once you get into it. |

That little motor is is rated at 50 watts or 0.067 hp :) |

|

The Story of Two Fans

Well, I am in need of some kind of air cleaner for my

shop, I know how harmful this stuff is for your health, all that fine

dust, plus I hate wiping it off of everything. I needed a fan of some

kind, I was out a the recycle shop, looking for a desk for my eldest daughter

(she wants one real bad, and the workshop in not set up yet) and I found

these kitchen vent hoods for about $20. Brand new, never been used. I

opened the boxes myself. I even got a 6 month warranty from the recycle

shop. They are rated at 590 cubic meters per hour, quick bit of math, and

that is 20832.9 cubic feet per hour divided by 60 minutes is 347.4 cubic

feet a minute. I noticed that the Grizzly basic air cleaner is 510 CFM, so

it is not that high, but I did buy two of them. One other advantage is

that they are very flat, and will fit up tight against the ceiling. I

won't be using the stock steel cabinets that they came in, too many leaks,

and I want to make them more compact.

I have the mind to make kind of a mini cyclone with

one, I wonder if it would work? The CFM one a portable DC is about

350, but the static pressure is 2.76, on the Grizzly item, and I really

doubt that the kitchen fan is anywhere near that. I should just break down

and buy a proper motor for the cyclone and go from there.

I have been looking for a fan to make an air cleaner from

an AC shop etc. for over a year, no go. You see, the squirrel cage fans

here in the AC units are about a 3" diameter and about 2' long, not

of much use. We don't have central heating, so those types of furnace fans

are not common. I figure that for $20 a piece they were worth it. |

Testing, yes they work! |

Big Time Router Gloat!

Now this is a real gloat. A Hitachi M12 router, everything

works great, not too old, picked it up for $50!

It is missing all of the accessories, but I can get what I need. I have a

Hitachi M8, that will be for hand held stuff, this I will build into a

router table. there is also a straight cut carbide tipped bit with it,

1/2" shank, about 1 1/2" cutting surface, a bit rusty, but

should clean up OK. It is about a 3/4" bit. That, here in Japan, is

worth well over what I paid for the router. I also got a 6 month warranty

on this item. |

|

|

The Toolbox

Gloat

If you painted this unit read and put a Snap-On logo on it

how much would it cost? This is a set of drawers designed to be filled

with paper, like at an art supply shop, or a printing shop. It is very

heavy duty. the steel is of a heavy gauge, it should work well as a tool

box. I have the idea to put it on a mobile base, and to put a wooden top

on it that extends out a few inches on all sides. I might even put a tail

vice on it, and some dog holes, it would make a very good mobile work

surface. the drawers are about 3" in depth, which is perfect for hand

tools, no more digging through drawers, everything can be laid out where

you can see it. I will line the bottoms of the drawers with that black

toolbox drawer liner stuff. Oh, BTW, I picked this up for about $40.

Should be good! |

| Update

Oct 3rd!

I got busy and put the toolbox on wheels and built a top for it. The

top is made out of 2 x 4s ripped in half, and raised up on 3 x 3s. This

should give me a good solid work surface to clamp things on . I figure

that the whole box will weigh a bit when full, so it should be on wheels

so I can move it around to places I'm working. It is a bit tall, so I may

go for some shorter wheels, we'll see.

|

Last Gloat

In the background of this picture you can see two sets of fluorescent

twin tube lights leaning against the wall. You guys may find them cheap at

the big box stores, well they are not cheap here. I found lights like this

at an electrical wholesaler, and they were about $100 a pop! At our

version of a big box store they were about $50 a pop, (made in China) this

is without tubes or starters. Well I got these at the same recycle shop

for about $15 a piece, and they had the tubes and starters included. They

were brand new, well almost, used once in a trade show for one week. Right

now I have eighteen 40 W fluorescent lights in my shop for a total

of 720 W of light, with the addition of these lights eight x 40W = 340

I'll have 1040 W of light in a 24' x 14' shop, now that should do it! |

Itsy Bitsy Can

of beer

The one on the left is 135 ml of beer or 4.57 ounces.

When only a taste is needed! |

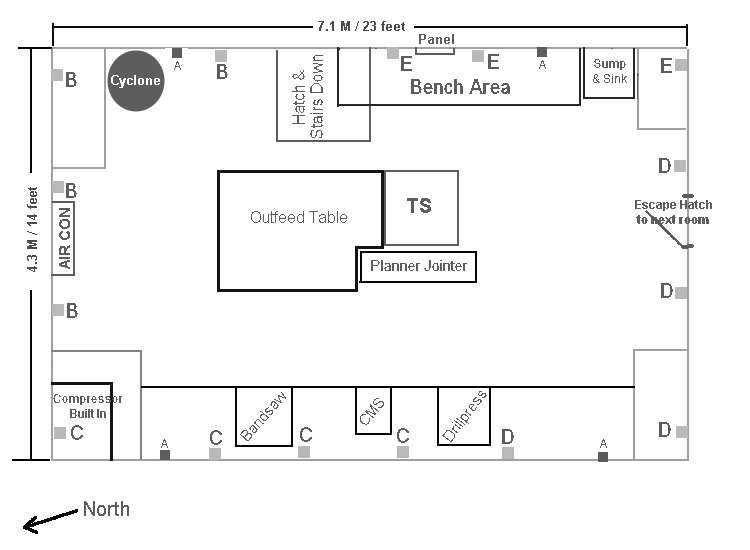

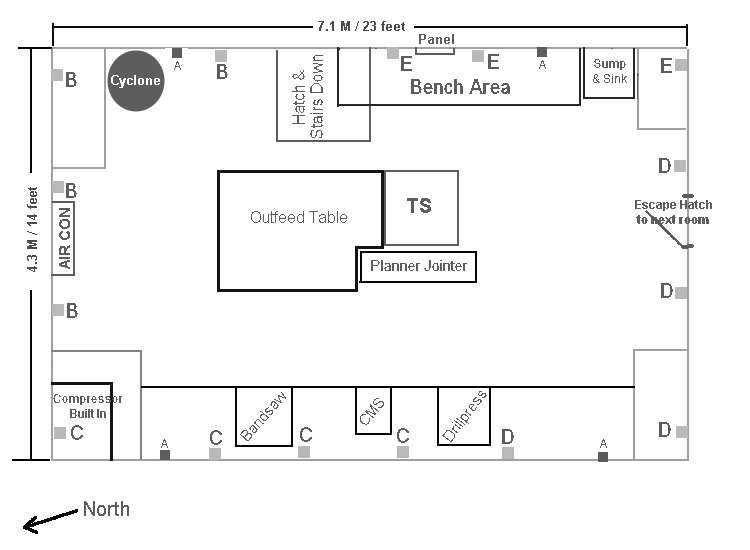

Here is a very crude drawing of my workshop layout. The electrical panel

is in the East wall near the ceiling just South of the hatch. The square

or rectangular things you see in the corners are the concrete

"benches" I have around the workshop. Look through the pages and

you'll understand. The black squares with an "A" are the four

existing outlets, they are 1' off the ground and I will move them up to

bench height. The gray squares with the various letters on them are where

I plan to put the rest of the outlets. I figure that too many outlets is

better than too few. I want to make four circuits of 4 outlets each. Now

here is the question, should they be side by side "B B B B" or

should they be somewhat staggered around

"B C D E" or maybe " B C B C" and "D E D E

"

The Air Con and two ceiling lights are on a separate panel from outside

the workshop, because I am a little short on power and I wanted there to

be some lights on if I blow the breaker in the shop. It will be more work

to stagger the outlet layout, but I wonder if it would be worthwhile to do

so. I want to get my walls up soon, I have all of the studs and I will

screw and glue them to the walls, but I want to run my electrical first. I

will then insulate and put the wall board up. on that subject I have not

decided, I can get plywood for almost the same price as drywall, the

plywood would be tough and I could hang anything anywhere.

For the Table saw "TS" I will run a line under the floor, I will

also put in a line for the planner and jointer, as I will put them

alongside the TS when I get them The CMS is on the west wall in a tool

line with a Bandsaw Drill Press and whatever else I am missing. Below the

panel on the East wall I'll put my main bench and cabinets. At the foot of

the stairs in the corner I plan on putting a cyclone, this is not too

close to the tools, but it is close to where i have to go to dump the

sawdust bin. The max distance from the cyclone to a tool will be only

about 5 meters, not far at all. I plan on steel spiral pipe, no need to

fool around with anything else.

I've got loads more questions, this is just a primer.

Cheers! |

| July

2002 Update!! |

I finally got around to making a proper out feed table/work bench |

It lines up about 1/16" below the table saw top, it is 180 cm x

90 cm, and 95 cm tall. The top is mad of two 9 mm thick pieces of plywood

screwed and glued together, the legs are 4 x 4s and the rails are 2 x 4s.

It is a good solid table. |

A view from the table saw end, wow look at all the junk piled in the

corner!! |

A look underneath. I was able to fit my dust collector for the table

saw here too. |

Well that's it for now, I have to get back to my work, work.

|

|

My wife made this Christmas arrangement and needed something to put

it on. I made this pedestal stand for her. The stand and the arrangement

sits in our building entrance. Kind of neat what you can do with the

various lighting (halogen and fluorescent) and the various settings on

the digital camera.

Cheers! |

These are a set of storage bins I made. I got really tired of hunting

through cardboard boxes of stuff I brought over from the old shop, but I

was not ready yet to build my cabinets as I have not had the time to do

the walls and floor. The bins cost about 150 yen each, and there are 7 in a

stand. The stand is on casters so I can move it about the shop. The bins

are 16" x 12" x 7".

Cheers!

|

Two things here, first you can see the wood storage rack I finally

built, and I

moved my SCMS under the new rack, I think this is the best place for

it.

I want to make a better bench/cabinet for the SCMS, but I have other

things

that need to be done first, and this set-up while not perfect by a long

ways, DOES work. |

|

Pat Copper's Brother Jack stopped by, nice guy, we took some

pics!

Jack in my shop!

Back to page one?

|