_____Stu's___Dungeon__

Joyful Honda

Treasure

Lesson Room Cabs

In the beginning

2

3 4 5

6 7 8

9

10 11

12 13 14

15

Jointer1

Jointer2

Router

Table1

Router Table 2

The Doors

Do

Pa

Give Me A Brake

Cyclone

Cyclone 2

Cyclone

3

Cyclone 4

Liquor

Shop Reno Tenjinsama Shrine Tree Tour

Beer Shelves

Wine Shelves

Five Cuts

Drill Press <NEW

DoPa 2007 <NEW

Turning

Jean Francious Escoulen

Eli Avisera Demo Day One

Eli Avisera Day Two

Lathe Stand!!

Turning

Roughing

It

Sharpening Station

Bowl Blank Processing

Captured Hollowing Rig

<NEW

Logging In Tokyo

Woodlot Woodlot

2006 Woodlot

3 Woodlot 4

Chainsaw Mill

Chainsaw

Mill Mk II

BIG BLUE

I won this Hitachi B601 Re-saw Bandsaw on Yahoo auction here in Japan, I paid 55,000 yen for it, a bit much, I thought, but once I got it home, an made a safe one point landing in the Dungeon, well I'm impressed. Sure it needs some TLC, and paint, but this thing is built for bear!!

Can we say HEAVY!!!

I had to get a hand from the old guy I bought if off of

getting it into the back of my van, this thing is heavy! I could really feel the

weight of it on the drive home. The blade is 63 mm wide, or about 2 1/2", a

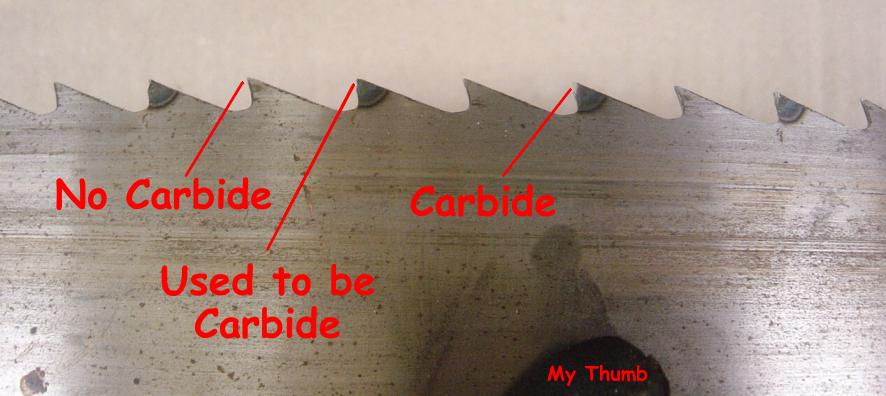

serious re-saw blade. I'm going to need a new one, the old one still cuts, but

it is in rough shape, most of the carbide tips are missing..

I'm a bit worried about how much a new blade will cost me...

The blade is just about 260 cm long, or 102 1/4"...? Is this a standard size? I'll have to find out.

Here it is unmasked

From the left

From the right

A pic of the motor, it has a gear box on it,

which would stop me from putting a bigger motor on there...easily

The wheels have no rubber on them, they so have an area that is slightly

lower,

this would allow for the teeth in the blade, I assume.

Here are the two knobs on the top for adjusting the run-out and the

tension,

they work fine, if a bit rusty

This is one of the blade guides, some kind of low friction plastic I guess.

The Bandsaw needs a serious tune up, but the bearing on

both wheels spin easily,

and the motor sounds fine (the gearbox makes a bit of noise, I'll see it I

can lube it).

I think that with a bit of paint, and some TLC this is going to be one heck of a

re-saw bandsaw.

Wish me luck!!

OK I tore the old Bandsaw down to the bones....

The I tore it down some more...

The

steel in this "H" frame is about 1/2" thick!!

With just the frame it is still heavy, but I should be able to lift it onto the

stand I'm going to build....

More pics...

This is the pile of parts I have....

Some paint and I'll be putting it all back together!!

OK the Painting is almost done....

This part, being steel, like steel tubing cleaned up nicely and took paint

really well.

Some of the other pieces, the cast stuff, seemed to have absorbed the grease

and or oil on them, and were a lot more work to clean.

Oh well, should look good when you take into account the way

it looked when I picked it up.

After all, it is not a car or something, I don't think that spending the time to

get everything absolutely perfect is time well spent.

I'm quite happy with how the table top is turning out, I have run out of sanding

discs, so I got to wait to finish it.

OK sleep is for whusses...

I still need to fix the guides and get a new blade, mount the motor, but hey,

looking good I think!!

A little before and after action!

Going Mobile!!

I need a base for Big Blue, I've decided to put it next to the

SCMS,

so I needed to make the table top of Big Blue the same as the SCMS's

table.

I think the saw will be in one place for most cutting,

but if and when I get much larger pieces to cut,

I'll have to move the saw out, to give me more in and outfeed room.

I needed to make the saw mobile, as well as make it the right height.

I made a base out of 2x8s, 2x6s and some 4x4s.

NO NEW WOOD WAS USED

all scrapes, and even some pieces from the base that Big Blue came on.....

Here is the view of the base from the under side.

You can see how the two sets of 4x4s will go to support the saw,

it is after all on heavy saw, so the base has to be up to it.

Now I just have to add the wheels and the blocks

wheels and blocks, yes the blocks are held on with glue and pocket screws!

a good 12" of re-saw capacity!!

That will be the usual height of the blade guard and guide

Another angle

OK we have a nice 4 point landing!!

This sucker is NOT portable, I could not even sort of lift it straight

up...

Tip it back on the to it's wheels, and it is mobile for sure!!

Look, only one hand!!

Now I wait for parts, next week they say, can you believe that? "Made in Japan" right on the box, and I live in Tokyo, but it take two freaking weeks to get parts......?

Nov 15th...

Still no phone call so no parts!!

OK I moved Big Blue into place, so now it is parked!!

One thing about moving new equipment into place is it makes a mess,

as most often when you move one piece, you have to move something else first.

Just fit under the wood rack, when you are good and lucky it comes together!!

The other thing I did today was to run new lines for power,

I had not run any new lines for outlets, as I wanted to let things find their

place in the shop first,

that is mostly done now, and I have a very good idea where stuff will call

home,

so now I can run the power to those places, which I was in the process of doing

here.

On to the next thing...

I've been wanting to upgrade my table saw's fence for a while,

but I've yet to see a system that bolts on to the DeWalt 144 I have.

A nice piece of extruded aluminum would be nice too, but I

could not find it here in Japan.

Well the other day at the home center I found this box shaped tubing with kind

of an "X" in the middle of it. It is used to make shelving out of.

I wanted to put it right on top of the fence, but the support thing for doing wide cut would then not swing over the fence. I cut the piece of aluminum tube and the piece of white Oak I put on the fence, worked well I think.

Now I need to make me some hold-downs and feather board etc.

Cheers!