_____Stu's___Dungeon__

Joyful Honda

Treasure

Lesson Room Cabs

In the beginning

2

3 4 5

6 7 8

9

10 11

12 13 14

15

Jointer1

Jointer2

Router

Table1

Router Table 2

The Doors

Do

Pa

Give Me A Brake

Cyclone

Cyclone 2

Cyclone

3

Cyclone 4

Liquor

Shop Reno Tenjinsama Shrine Tree Tour

Beer Shelves

Wine Shelves

Five Cuts

Drill Press <NEW

DoPa 2007 <NEW

Turning

Jean Francious Escoulen

Eli Avisera Demo Day One

Eli Avisera Day Two

Lathe Stand!!

Turning

Roughing

It

Sharpening Station

Bowl Blank Processing

Captured Hollowing Rig

<NEW

Logging In Tokyo

Woodlot Woodlot

2006 Woodlot

3 Woodlot 4

Chainsaw Mill

Chainsaw

Mill Mk II

Page 15

As the summer winds down here in Japan, and we get back to

work and to school,

I realize that I've not gotten nearly as much done as I had hoped.

Part of this is because we have been busier than usual,

and partly because this year we don't have a part time worker at the

liquor shop.

We also have the kids home this summer, not in Canada.

It all adds up to one busy summer with little free time,

at least I'm not bored!

I went down to the Dungeon with the intention of getting the

sheet stock

cut up for a set of drawers to slide under our bed, that will be used for storage.

I got all the head scratching done, figuring it all out,

but when I went to begin ripping up stock,

I was thinking about all the side and front pieces that would be needed in

the same size,

I began to look at my SCMS's fence and table with less than admiration.

The SCMS table and fence were whipped up to "Get-R-Done"

The old set up.

I still had most of a piece of the aluminum extruded stuff I

used for the router table's fence,

so I thought I'd put that to good use.....

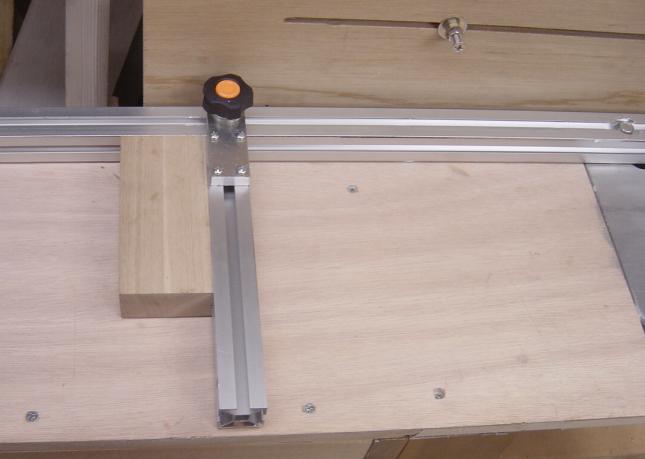

This is what I came up with.

I know that when I go to cut some miters I'll have to cut the fence a bit,

but I'll do that when I have to, now it just just nice having a long fence with

a moveable stop.

Nothing fancy, just a couple of chunks of aluminum,

the one under the knob is backed up on the back side of the fence with

another pieces,

so the fence has a piece on all three sides. The wooden block is part of the

stop,

it gives it a squared surface to seat against.

I've only used it a few time, but it is a big improvement over the old set up.

Whoops, Mark II

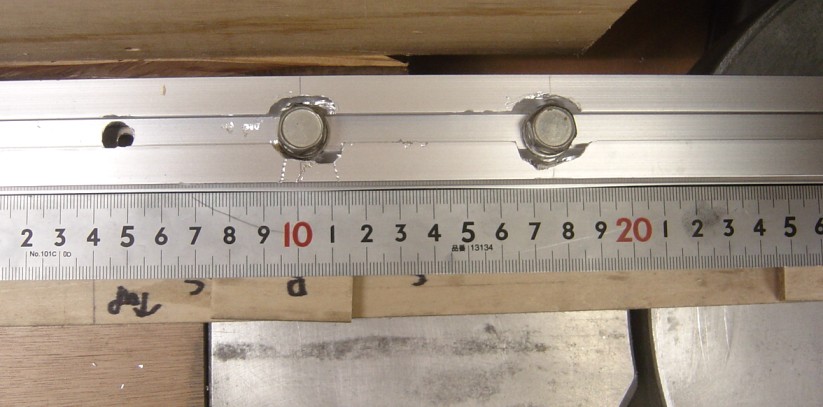

OK, I had a bit of a problem, well two problems.

1)The aluminum fence was deformed by tightening the bolts down....

This was not going to work.

The second problem was that I could not slide the stop close to the stop, the bolts were in the way of the stop sliding close.

To solve these problems, I put the stock pieces back, and then put wooden fences with the aluminum track on top.

I ended up with a better solution, IMHO, this lets me slide the stop to very

near the saw,

and because the track is now held on by screws, and is not the main fence, it is

not squished.

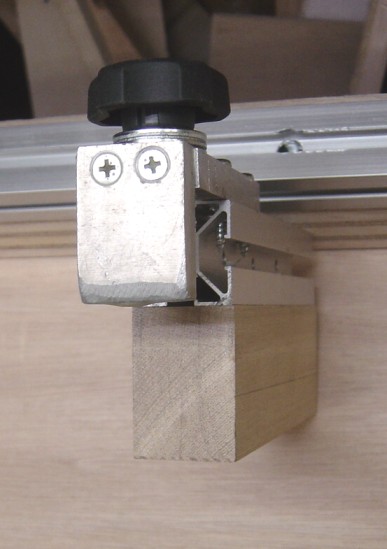

A view from the right side

Here you can see the back side of the stop, and how the track is captured on

three sides

A close up of the back side of the stop

I think this is much better than the first version, but who knows, you may yet see a "Mark III"

Cheers!

On To Making Some Sawdust!!

My

lovely wife wants some more storage, the one place I can think of that is not

used at the moment is under our bed.

I plan on making a bunch of "drawers" that are on wheels and can just

be pulled out from under the bed.

There would be no tracks to keep them in place, they would just be organized

under the bed.

To do this I need to cut up a bunch of sheet goods, I need to cut a bunch of 21

cm tall sides and fronts for the drawers.

The best way to get the stock out of my 3'x6' sheets of plywood is to cut these

pieces on the short side, not lengthwise.

I need a total of 28 pieces to make the drawers.

I came up with a very simple but quick method to do this.

Using my cut off guide, I made two "T" spacers, these will put the cutting guide at exactly 21cm from the edge....

T-stop for setting the cutting guide

Using the T-stops, the cutting guide is set in place

Here is it at the end of the cut, the rope holds up the vacuum hose out of the

way,

and there is a hook on the rope to hang the circular saw on.

OK the saw is hung out of the way, and the piece is ready to remove.

Then remove the clamps, and move the whole shebang forward for the next cut.

Cut and unclamped, ready to move to the next piece and start the whole process

again.

In 30 minutes I cut up 3 1/2 sheets of plywood for the drawers.

I hope someone gets some ideas from this.

Cheers!

More stuff going on in the Dungeon......

Amp me up!

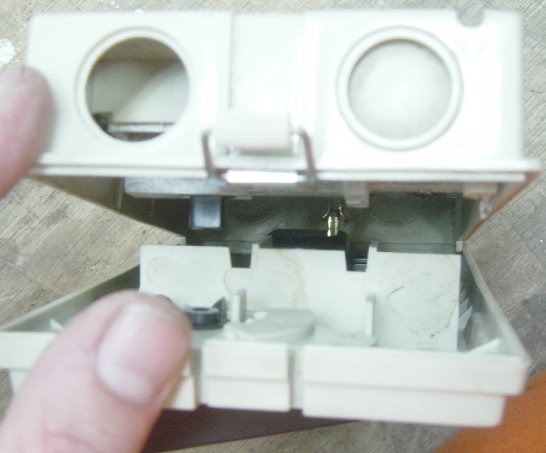

I wanted an amp meter for my cyclone, one

that would be permanent.

I found this one on Yahoo auction

It is actually a kind of on/off switch/breaker with an amp meter built in.

I paid about $20 for it with shipping.

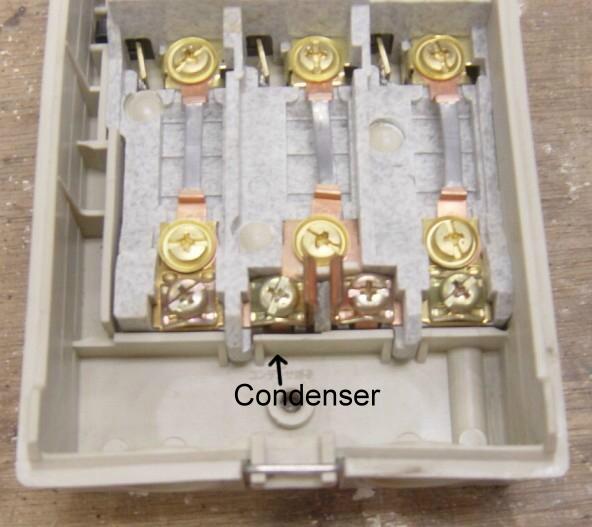

It hinges open and you can see the three poles, they have the old fashioned

fuses, but I guess it will work

and another shot of the inside.

The black thing in the pic, in the middle is the back of the amp meter,

it has a stub on it that mates with the backside of the unit.

A close up of the back of the amp meter, the stub seems to be in two pieces,

with an insulator between them.

I guess this is how it reads the amps.

From the top down, you can see the stub going into its contact

A side shot of the two pieces making contact.

The middle leg where the amp meter attaches has two screws on it,

below the screw on the left it says Condenser. I wonder how I'm supposed to hook

this up.

I guess I got to bug some sparkies I know!!

Cheers!